How Freeze Drying Works: Benefits, Uses, and Step-by-Step Guide - Freeze Dry Insights

- Home

- Start Here

- How Freeze…

How freeze drying works

The Interesting Journey Through Time: History of Lyophilization

The story of freeze drying begins long before the machines of modern laboratories. Ancient Andean civilizations discovered a natural form of this process thousands of years ago, when farmers would leave potatoes out overnight, where freezing temperatures and thin mountain air worked together to draw out the water. Over several nights they made lightweight potatoes that could last for years and serve as a vital food source during hard times. They named it “chuño,”

In early 20th century, scientists tried to replicate this natural phenomenon in controlled environments. This research led to the invention of freeze dryers. Early use of lyophilization was critical during World War II, when the technique was used to preserve blood plasma and penicillin for soldiers on the battlefield. These innovations proved that freeze drying could save lives by preserving food.

Over time, food scientists and engineers began applying it to preserve coffee, fruits, and entire meals. Today, lyophilization has been mastered to preserve food and medicine and even helps out in exploring space.

The Science behind freeze drying: Sublimation

Sublimation is the direct transition of a substance from solid to gas without ever becoming a liquid. Imagine placing an ice cube in a vacuum chamber and watching it vanish into thin air without melting into a puddle. That is sublimation. A simple everyday example is dry ice, which skips the liquid phase entirely and transforms straight from solid carbon dioxide into a gas.

This step is crucial for food preservation. Sublimation avoids the liquid phase and leaves food intact with its original texture, nutrients, and appearance.

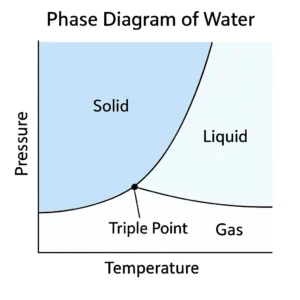

To understand how freeze dryers make this possible, we need to explore a fascinating concept in physics: the triple point of water. The triple point is the unique set of conditions where water can exist as solid, liquid, and gas simultaneously. Think of it as a “sweet spot” where all three phases are possible at once. For water, this occurs at just above 0°C and a very specific low pressure.

Freeze dryers make this happen by manipulating temperature and pressure to stay below the triple point. In this carefully controlled environment, ice cannot melt—it can only sublimate directly into vapor.

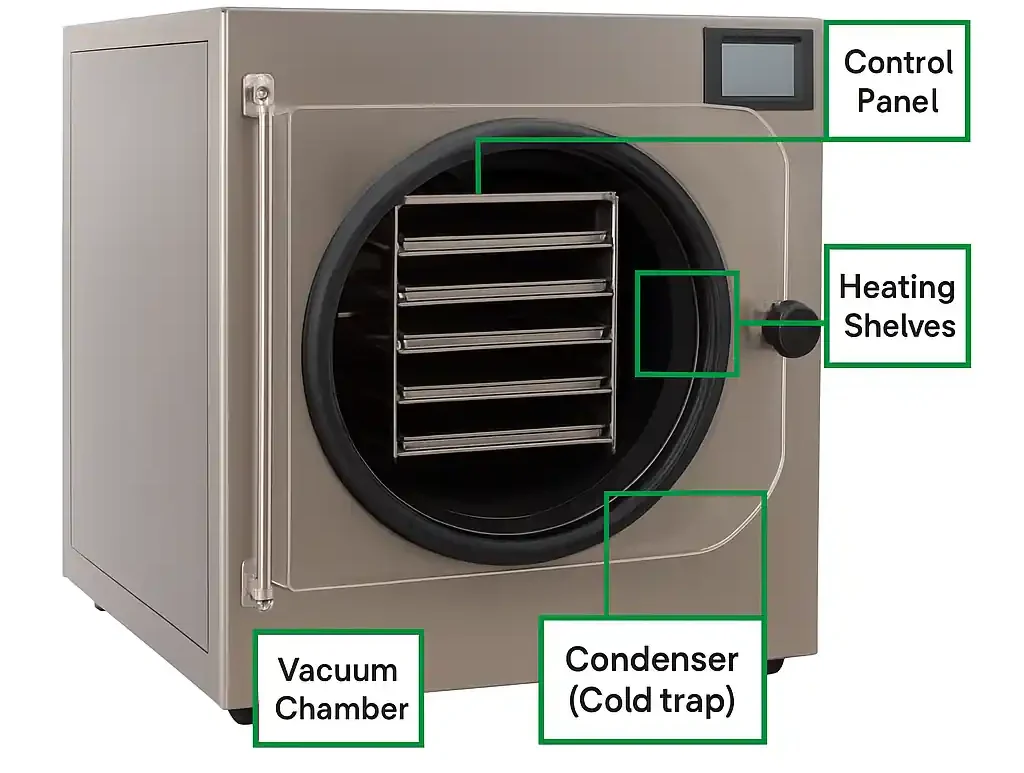

Behind the Scenes: The Anatomy of a Freeze Dryer

To bring this performance to life, specialized equipment works quietly behind the scenes. Each component of a freeze dryer plays a distinct role in making it possible.

Vacuum Chamber

The main stage where the product rests. By lowering the pressure inside, the chamber allows ice to sublimate without melting.

Condenser (Cold Trap)

A super-cold surface, typically between -40°C and -80°C, that captures water vapor by freezing it into solid ice. This prevents the vapor from re-entering the chamber.

Vacuum Pump

Creates and maintains the low-pressure environment, enabling sublimation to occur efficiently.

Heating Shelves

Deliver carefully controlled heat to the product. The warmth is gentle and precise, sublimating the food without melting it.

Control System

The “brains” of the operation, monitoring and adjusting the temperature, pressure, and drying time to ensure success.

Click and interact with the infographic below to understand the anatomy of a freeze dryer

Title

Body

Why Choose Freeze Drying? Major Advantages

Freeze drying stands apart from other preservation methods because it protects both the integrity and the quality of food. By understanding its advantages, you can see why it has become the method of choice for everything from emergency rations to astronaut meals and why I, as a food scientist, adore this process.

Superior Nutrient Retention

Since freeze drying relies on low temperatures, delicate vitamins, minerals, and antioxidants survive far better than in heat-based preservation methods. Nutrients like vitamin C, which quickly degrade under high heat, are largely retained in freeze-dried produce. Research from the USDA and NCBI shows freeze-dried fruits and vegetables often retain over 90% of their nutrients.

Preservation of Original Shape and Texture

Because water escapes as vapor without passing through a liquid stage, the product retains its cellular structure. Foods remain porous and sponge-like, closely resembling their fresh form. Once rehydrated, they return to their original texture, something simple dehydration cannot achieve.

Extended Shelf Life

With nearly all moisture removed, bacteria, mold, and enzymatic activity cannot thrive. Properly packaged freeze-dried food can last 20 to 30 years without refrigeration, making it one of the most reliable methods for long-term storage.

Lightweight and Compact Results

Water removal drastically reduces weight and bulk, making freeze-dried foods perfect for backpacking, emergency kits, and space missions. NASA includes freeze-dried meals in astronaut diets because they are light, nutrient-rich, and easy to store.

Enhanced Flavor and Aroma

Since freeze drying avoids high heat, delicate volatile compounds responsible for flavor and aroma remain intact. That’s why freeze-dried strawberries taste much closer to fresh fruit compared to dehydrated ones.

What Can (and Cannot) Be Freeze-Dried?

One of the reasons freeze drying has become so valuable is the huge range of choices you have. Everyday snacks to pet food, deserts, treats and medicines, you can process can preserve an impressive variety of products.

Commonly Freeze-Dried Items

- Fruits: Berries, apples, bananas, and peaches retain bright flavors and natural sweetness.

- Vegetables: Corn, peas, carrots, broccoli, and spinach rehydrate beautifully while keeping nutritional value.

- Meats: Cooked chicken, beef, and ground meats offer protein-rich long-term options.

- Dairy: Foods like ice cream and cheese can be freeze-dried, creating unique textures (e.g. astronaut ice cream).

- Full Meals: Stews, chili, and pasta dishes preserve completely, ready to rehydrate into hot meals.

- Specialty Items: Instant coffee, medicinal herbs, flowers, vaccines, and antibiotics are also preserved this way.

Items Less Suitable for Freeze Drying

- High-Fat Foods: Peanut butter or butter go rancid since oils cannot be effectively removed.

- High-Sugar Foods: Pure honey or syrup remain sticky and fail to dry properly.

- Low-Moisture Foods: Crackers and chips are already dehydrated, so freeze drying adds no benefit.

- Pure Liquids: Challenging unless concentrated or used in specialized scientific applications.

Let me help you set realistic expectations for what freeze drying can give you. To excel in this art you need to use it efficiently.

Freeze Drying vs. Dehydration: A Head-to-Head Comparison

Because both freeze drying and dehydration remove water to preserve food, it is easy to confuse the two. Yet, the scientific principles behind them are quite different, leading to distinct results in texture, nutrition, and shelf life.

| Attribute | Freeze Drying | Dehydration |

|---|---|---|

| Water Removal Method | Sublimation (ice turns directly to vapor) under vacuum and low temperature. | Evaporation (liquid water turns to vapor) using heat and airflow. |

| Temperature Used | Very low (freezing first, then gentle heat for sublimation). | Moderate to high (typically 120°F – 160°F / 50°C – 70°C). |

| Resulting Texture | Light, airy, often crunchy; retains original shape and porous structure. | Chewy, leathery, or brittle; foods often shrink and toughen. |

| Nutrient Retention | Excellent; most heat-sensitive vitamins, antioxidants, and enzymes are preserved. | Variable; heat-sensitive nutrients can be degraded or lost. |

| Rehydration | Very rapid and complete; restores close to the original form. | Slower and often incomplete; texture may not fully return. |

| Shelf Life | Extremely long (20–30 years when properly packaged). | Moderate (1–5 years depending on the food and storage conditions). |

| Weight Reduction | Up to 95% of original weight removed. | Up to 80–90% of original weight removed. |

| Energy Consumption | Higher upfront due to freezing and vacuum systems. | Lower per batch, though longer drying times may offset efficiency. |

| Cost of Equipment | Higher (home freeze dryers and industrial units can be expensive). | Lower (affordable food dehydrators or simple oven setups). |

| Best For | Delicate foods, long-term storage, high nutritional preservation. | Chewy snacks, short- to mid-term preservation, reducing bulk. |

Unmasking Myths: Common Misconceptions About Freeze Drying

Fact: In reality, freeze drying preserves more nutrients than most other preservation methods. Because the process happens at low temperatures and under low pressure.. Compared to canning or heat dehydration, freeze drying offers some of the highest nutrient retention.

Fact: While both methods remove water, the science behind them is entirely different. Freeze drying relies on sublimation, where ice turns directly into vapor. Dehydration uses heat and airflow to evaporate liquid water. As explained in the comparison table above, this difference leads to major variations in shelf life, texture, and nutritional value.

Fact: Although freeze-dried meals gained fame through NASA space missions and emergency kits, today they are very popular in everyday life. Home freeze dryers allow families to preserve seasonal produce. Chefs use freeze-dried ingredients to intensify flavors in creative dishes. Even snack companies now market freeze-dried fruit crisps and yogurt bites for casual munching.

Fact: Quite the opposite. Because flavor compounds are preserved at low temperatures, freeze-dried foods often taste more rich. A freeze-dried strawberry, for example, delivers an intense burst of flavor that rivals the fresh fruit. After rehydration most foods return close to their original taste and texture.

Fact: Freeze drying is purely physical. No additives, preservatives, or chemical reactions are involved. The process simply manipulates temperature and pressure to remove water safely. What you eat is the same food you started with, just without the moisture.

Key Takeaways

- • Sublimation is the core mechanism, simply protecting food and materials without damage.

- • Freeze drying offers superior advantages over other preservation methods.

- • Its uses are well beyond food. But is a very nice thing to have in every home.

- • Technology is advancing, making it more accessible and more sustainable.

As you continue your journey of discovery, I'm here to let you know that I am your go-to person for any help regarding freeze drying your food at home or even using it as a successful business. This guide is based on established food science and peer-reviewed research, and years of my experience in commercial freeze drying as well as a mom in the kitchen who loves to make lovely snacks for her loved ones.